Laminated Non woven Fabric

Laminated Non woven Fabric

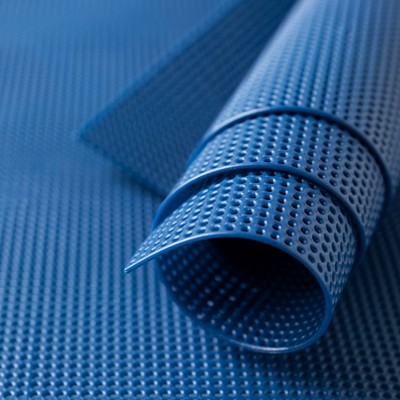

Laminated nonwoven fabric refers to a material that consists of layers of nonwoven fabric that are bonded together using a lamination process. This involves combining multiple layers of nonwoven material with a layer of film or another material, typically through the application of heat, pressure, or an adhesive. The lamination process enhances the properties of the fabric and imparts additional features that may not be present in the individual layers. Here are some key points about laminated nonwoven fabric

Lamination Process

- Heat and Pressure

Lamination is often achieved by applying heat and pressure to fuse the layers together.

- Adhesive

Some laminated fabrics may use adhesives to bond the layers together.

Material Composition

- Heat and Pressure

Lamination is often achieved by applying heat and pressure to fuse the layers together.

- Adhesive

Some laminated fabrics may use adhesives to bond the layers together.

Characteristics and Advantages

- Enhanced Strength and Durability

Laminating layers improves the overall strength and durability of the nonwoven fabric

- Water Resistance

The lamination process can add water-resistant or waterproof properties to the fabric, depending on the type of film used.

- Barrier Properties

Laminated nonwoven fabric can provide barrier properties against liquids, chemicals, and other substances.

- Softness and Comfort

Depending on the type of lamination and film used, the fabric can retain a soft and comfortable feel.

- Customizable Properties

The lamination process allows for customization of properties such as breathability, transparency, and color.

Applications

- Medical and Healthcare

Laminated nonwoven fabrics are used in the production of medical gowns, drapes, and other protective apparel due to their barrier properties.

- Packaging

Laminated nonwovens are used in various packaging applications, providing strength and moisture resistance

- Outdoor and Protective Gear

Applications include rainwear, outdoor clothing, and protective covers.

- Hygiene Products

Diapers, sanitary napkins, and other hygiene products may use laminated nonwoven materials for enhanced performance.

- Industrial and Automotive

Laminated nonwovens are used in applications requiring resistance to chemicals, oils, or other substances.

Considerations

- Breathability

Depending on the specific lamination process and materials used, breathability can vary.re not woven together but rather bonded directly.

- Cost

Laminated nonwoven fabrics may be costlier than non-laminated alternatives due to the additional processing steps and materials.

Laminated nonwoven fabrics are versatile and find applications in a wide range of industries where enhanced strength, durability, and specific performance characteristics are required. The choice of materials and lamination process can be tailored to meet the specific needs of different applications.